Material Modeling on the Microscale by means of High-Resolution X-Ray Microscopy

© IWES / Nikolas Manousides

© IWES / Nikolas Manousides

| Led by: | Claudio Balzani |

| E-Mail: | research@iwes.uni-hannover.de |

| Team: | Nikolas Manousides |

| Year: | 2017 |

| Funding: | Internal Project |

| Duration: | since 2016 |

Project Description

The increasing requirements on fiber composite materials in wind energy demands a deeper understanding of the material and its mechanical behaviour. The processes on the microscale are especially important as these are difficult to characterise in a non-destructive manner. At the Institute for Wind Energy Systems, high-resolution X-ray microscopy is employed to investigate the damage behaviour of fiber composites and adhesives. For that purpose an X-ray microscope (Zeiss Xradia Versa 410) with an exceptional powerful X-ray source is utilised.

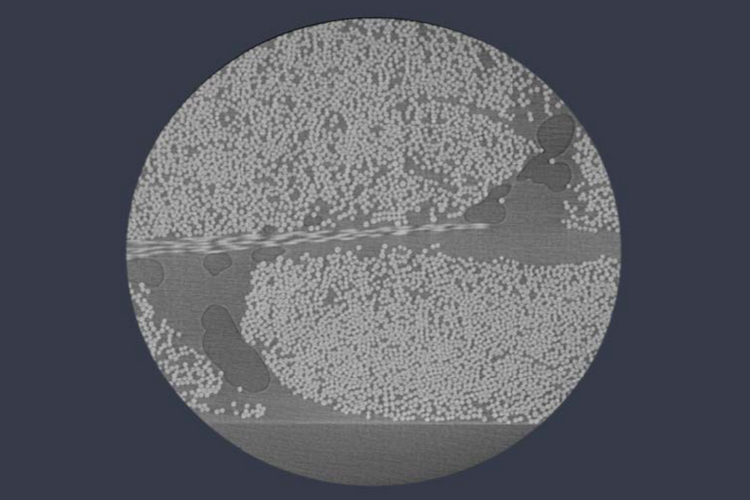

The specimen shown in the Figure is a uni-directional glass fiber/epoxy composite which is visualised in 3D via X-ray radiation. The specimen contains fibers (white dots in the picture), the matrix (light grey background), and flaws such as air inclusions (dark grey background). The advantage of non-destructive visualisation is the possibility to apply successively additional loads and to subsequently monitor changes in the material's microstructure. With this information, state-of-the-art material models can be updated and extended in order to bridge the boundaries of scalability and to increase the structural reliability of wind turbine rotor blades.